Co., Ltd. is the main business of Luoyang Hongte Machinery Equipment Co., Ltd., our company was originally China South Locomotive & Rolling Stock Factory Luoyang Locomotive Factory repair machine factory, according to the 2004 under the " The relevant provisions of the state restructuring for the Luoyang Hong special machinery and equipment Limited. The company mainly for the steel straightening cutting machine manufacturing sales, machinery and equipment overhaul, non-standard equipment manufacturing. The company is strong in technology, well-equipped, high technical staff quality. The company developed high-efficiency steel straightening cutting machine has reached the advanced level of similar foreign products, high efficiency, good quality, by domestic and foreign steel dealers, steel welded wire mesh production enterprises, steel distribution centers and other users of praise. Products have been exported to Laos Myanmar Southeast Asia, Taiwan and Europe. Welcome friends from all walks of life patrons, visit the guide.

直機(jī)切斷機(jī).jpg)

Straightening machine cutting machine for more information

Straightening machine cutting machine Brand: Hong special

Product alias: steel straightening machine cutting machine

Product use: straightening and cutting cut

Straightening machine cutting machine type: steel cutting machine

Model: GT5 / 10TW type, GT6 / 12TW type, strengthen GT6 / 12TW type, strengthen GT6 / 12TW type

Straightening machine cutting machine technical parameters

技術(shù)參數(shù)(4).jpg)

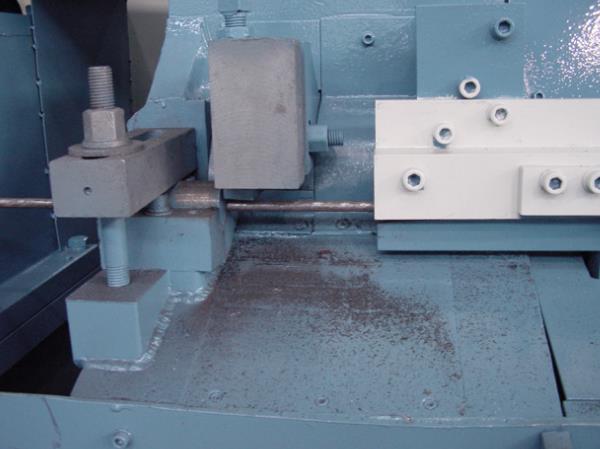

Straightening machine cutting machine product features

1. Straightening machine cutting machine speed: the machine's maximum cutting speed of 136 m / min, is the current homemade machine 3-4 times.

2. The scale of the standard: the characteristics of the machine is the size of precision, cut length error ≤ ± 1mm

3. Straightening accuracy: Straightening straight after the straightness of ≤ 2mm / m, higher than the accuracy of similar machines.

4. Can be shortened steel: the shortest control of the length of only 0.8 meters, is the current domestic machines can not be achieved. This is particularly useful for enterprises that produce steel wire mesh.

5. Straightening machine cutting machine for a variety of wire: the straightening part of the machine is unique, suitable for hot rolling / cold rolling / round / ribbed a variety of wire rods.

6. Intelligent control: The machine uses a programmable controller (PLC) for control, operation, adjustment is simple and reliable.

7. Low failure rate: As the parts processing fine, strict quality control, so the installation and commissioning, under normal working conditions, long-term maintenance without delay.

Safety Technology of Straight Cutter Cutting Machine

(1) When installing the receiving frame, the centerline of the trough chute shall be aligned with the center line of the guide bobbin, the straightening cylinder and the lower cutter hole.

(2) After installation, you should first check the electrical system and other components for damage, whether the machine is connected to a solid and reliable parts, the transmission part is flexible. Confirm that the parts are normal before they can be commissioned. Test run should check the bearing temperature, see the hammer, cutter and shear gear and other parts are normal. Confirm that no abnormal condition, before feeding, test straight and cut off.

(3) according to the need to straighten the diameter of the bar, choose the appropriate straight block, traction wheel groove and transmission speed. Adjust the diameter of the block should be larger than the diameter of steel bars 2mm ~ 5mm, traction wheel groove width, and should be required to straighten the diameter of the bar coincide.

(4) must pay attention to adjust the straight block. Adjust the simple, usually with five straight block, the first 1,5 two straight block to be placed on the center line, the middle three can be off the center line. First, the offset of about 3mm offset, after the test straight, such as steel is still slow bending, can gradually increase the offset until straightening.

(5) guide the front of the tube, should be installed a length of about 1m steel pipe. Need to straighten the steel should first pass through the pipe, and then penetrate the guide tube and adjust the barrel to prevent each plate near the straightening of the steel head when the end of the pop-up wounding.

(6) in the straight block is not fixed, the cover is not covered before, shall not penetrate the steel bar, to prevent the machine after the straight block to fly out of injury.

Straightening machine cutting machine products

直機(jī)切斷機(jī)1.jpg)