1, positive steel straightening machine equipment must be responsible for the person, and holders of certificates.

2, the operator is not allowed to leave the machine too far, on the plate, wearing silk, the first cut off must be carried out.

3, straightening the process of steel, when the steel out of the tray guide slot, the top fixed body and the chaos or steel bar off, should promptly press the limit switch, stop cutting steel, to be adjusted after the prospective use The

4, each steel bar to adjust to the end or straightening short steel bars, should be hand-held pipe escort guide to the guide and straighten the drum, so as to avoid the free swing when the accident occurred.

5, straighten the mold is not fixed, the protective cover is not covered before, are not allowed to penetrate the steel bar, to prevent the machine after the start, straighten the mold flew out of injury.

6, forward steel straightening machine in the course of operation, shall not adjust the drum, is strictly prohibited with gloves operation, and is strictly prohibited in the mechanical operation of the maintenance process.

7, has been straightened, cut off the steel, should be according to specifications, the number of roots divided into small bundles neatly, not allowed to chaos, to prevent the composition of steel, performance caused by different quality accidents, operations must be cut off the power.

8, strict implementation of the "cross operating principles" to ensure that machinery is in good condition.

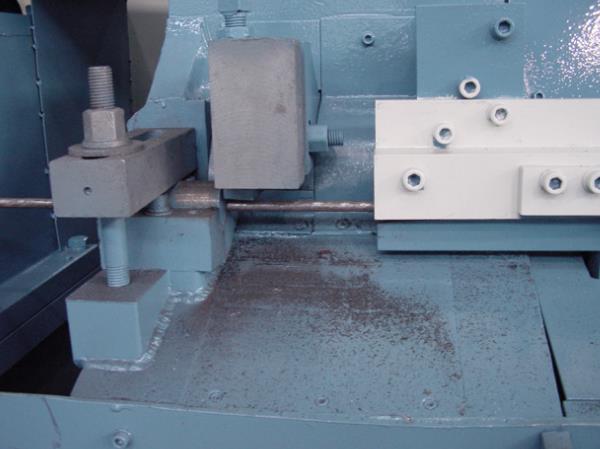

Forward steel straightening machine products:

場(chǎng) (1).jpg)

場(chǎng).jpg)