General machinery and equipment usually need to be maintained, reverse steel straightening machine is certainly no exception. Here, we provide some maintenance knowledge and attention, I believe we can give some help.

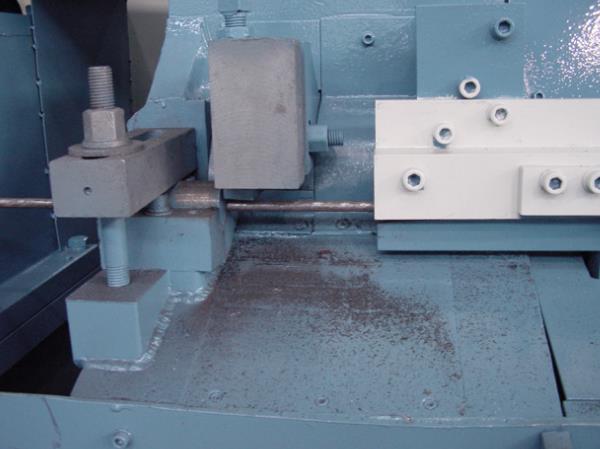

Mechanical parts of the parts between the greater friction, which will produce no small loss. So before each machine starts, it is best not to forget the rotation of the parts of the lubrication, ordinary lubricants can be, do not need how high-end. Machine time with a long time, there will be some minor failures. Regular inspection of the straight barrel is essential, at the same time to pay attention to a lot of straightening on both sides of the plane accumulation of oxide and rust, to ensure that the reverse steel straightening machine has the best straightening effect. Equipment work must pay attention to bearing temperature, more than 60 ℃, the parking should be appropriate cooling work, remember not to have luck. The entire structure of the machine to be well aware of the regular inspection is essential, sudden and fault problems to be resolved in a timely manner.

Reverse steel straightening machine products:

場.jpg)